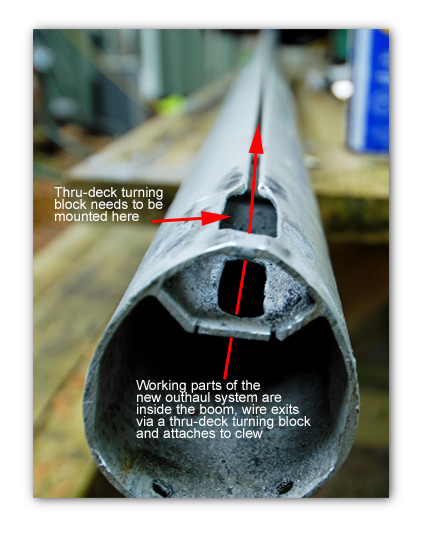

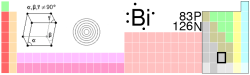

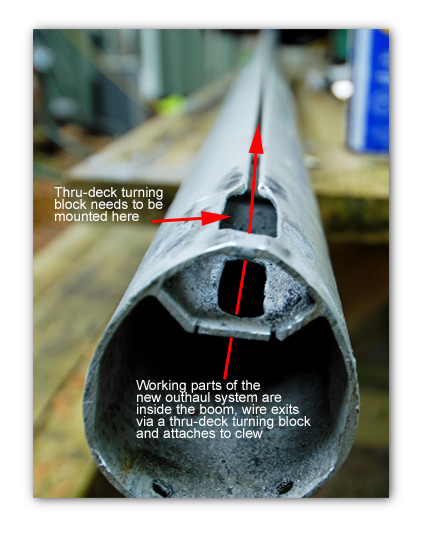

I’ve finally finished tweaking Madsu’s boom for the new internal outhaul system I mentioned a few days ago.

In order to make sure the outhaul doesn’t bind when pulling on the main, I figure I have to get the exit block at the end of the boom up as high as possible – which actually means mounting it in the sail track.

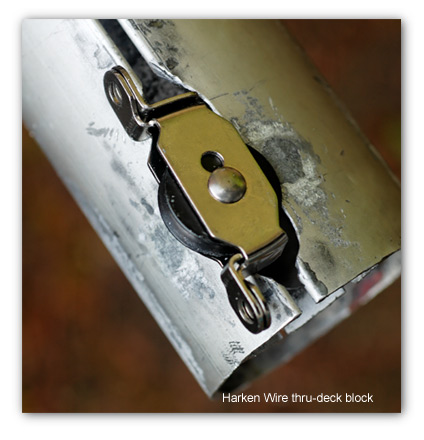

So the challenge here was how to mount the Harken thru-deck turning block in what is essentially the sail track. I also want the block to be rock-solid.

Working on the farm with my dad and uncles, they’d often have to tweak some piece of machinery – and in French they’d call that tweak a “patent”. Cleary, that’s what’s called for here.

All I really want to do is bolt the block in place, but there isn’t room for me to get a lock nut on the forward end of the block. I probably could rivet it in place, but I’m not convinced that’s going to work.

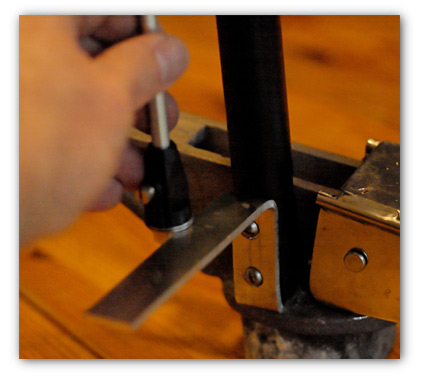

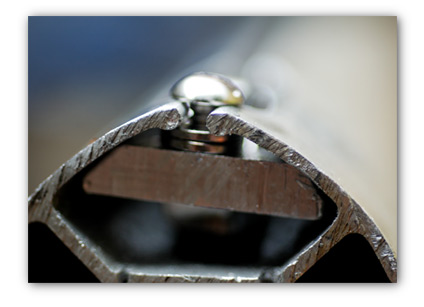

So, I figured I’d make an aluminum plate that will slide inside track, under the block. I’ll drill and tap for fasteners and it should all work ! The photo below shows how I want the block to sit, tight up against the slot in the boom.

I’m not really equipped to be machining parts, but I figured with my jig saw and a bench grinder, I should be able to make something that would work.

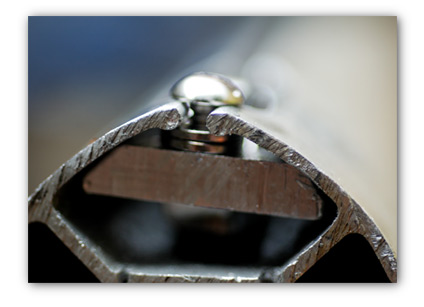

It isn’t pretty, but it’ll be out of sight anyway. Not the simplest thing to cut with a jig saw, I’ll say that much…

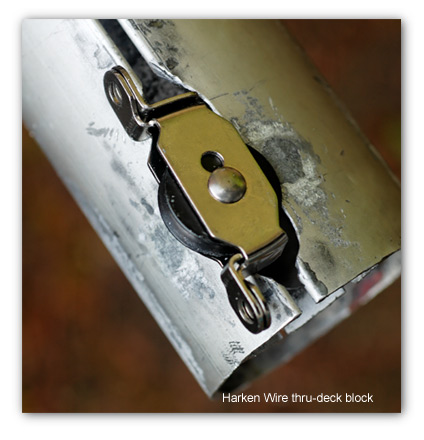

Here’s my “patent” when I slide it into the sail track.

The idea is that the thru-deck block is now sandwiched between my “patent” and the top of the sail track.

All I need to do now is drop in a stainless steel machine screw, tighten it up, and my exit thru-deck block is rock solid (I’ve left off the block cover so you can see the detail a bit better).

This was the last bit of detail I needed to finish on the boom before painting.

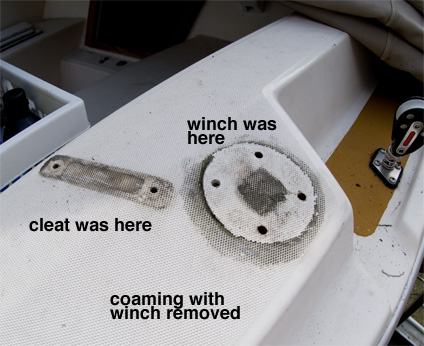

I’ve now drilled and tapped holes for all the boom hardware, including cheek-blocks for reefing lines, the outhaul exit block and cleat, and a few more bits of hardware for line management.

I’ve opted to simplify the reefing system quite a bit, just going to use a hook at the tack. For the clew, I’ll just use a single line attached to boom, up through the through the ‘new’ clew, down to a cheek-block on the other side of the boom, and forward to a cleat near the front of the boom.

Last season I was using a single line reefing system, with the line brought back to the cockpit. This was the set-up from the previous owner, and it was a nuisance.

For one, I was always going to the mast to lower the main halyard anyway, so having the reefing line in the cockpit was unhelpful. When not in use, the long line was always getting in the way no matter how often I stowed it, and when we dropped the main, it was even more in the way.

My new North Sails main has 2 reef points, so I’ve got 2 identical lines set up at the clew end. From their cheeck blocks they go forward along the boom, lead through beckets to the cleat.

The boom is stripped of all the hardware now, all the holes are drilled and tapped, so if the weather improved a bit I’ll try etching and painting the boom in the next few days