Another crappy weather day, so no painting today, but I did work inside on bits and pieces of Madsu’s gear.

Another crappy weather day, so no painting today, but I did work inside on bits and pieces of Madsu’s gear.

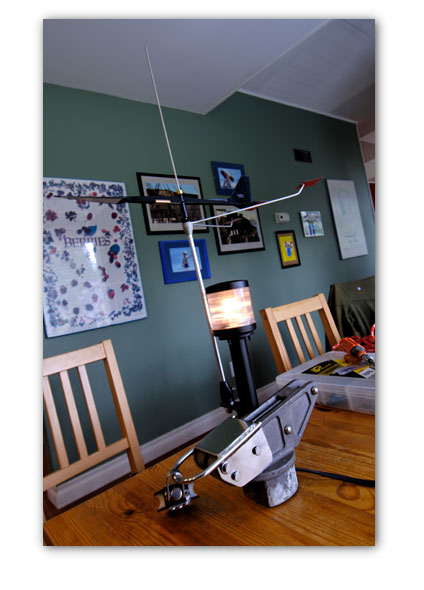

The masthead is done and ready to go. Yesterday I discovered that the new sheaves I got to replace the old wire sheaves didn’t actually fit.

I spent a bit of quality time with my Makita sander and the aluminum plate that acts as a spacer between the port and starboard pair of sheaves.

In the photo you can see the aft pair of sheaves – and the arrow points to the spacer that runs fore and aft and keeps the starboard side sheaves apart from the port side.

I didn’t want to sand too much since the sheaves just run free – there’s no bearings – the plastic sheave just runs on the pin – so I don’t want too much play in there.

The fit is perfect now – amazing what a little sandpaper on aluminum can do

With a new spin crane, a ridiculously expensive block for the spinnaker halyard, new anchor light post, Windex, and new sheaves for the all line halyards, Madsu’s sad little masthead has been transformed.

To keep me inspired while I’m working on this stuff, I’m reading There By No Dragons: How to Cross a Big Ocean in a Small Sailboat by Reese Palley.

(if you’re wondering what the hell that thing is sticking out of the TOP of the windvane, it’s the new ‘bird spike’ meant to keep freeloaders of the avian variety off the vane).

I should say that we sailed all last summer without the benefit of a masthead Windex. Instead we used Newport shroud telltales which were great, and we’ll keep them on board again this year.