We went out for an evening sail a few nights ago – a pretty big change in weather from even just a few days ago.

It was cool and threatening rain, and despite the weather office removing the wind warning, it was still gusty with lots of chop.

Our friends didn’t seem to mind – they were just happy to be out on a sailboat an d with Madsu’s main reefed and the 100% jib hanked on, we were making pretty good progress to weather.

We were the only sailboat out and tacked across from West Van to Bowen a couple of times.

I figured we should head in before it got too dark and colder. Reaching along the West Van shore near Whytecliff Park I decided to drop the jib and sail under main alone. It was now pretty much dark, and I dumped the main and lowered the motor to take us home.

Just as I pulled on the recoil cord to start the outboard, the cord snapped, right near the handle. It must have been really frayed as the pull didn’t even turn the motor over, and here I was with the pull start handle in my hand, the sails down, and the motor not running.

Fortunately, we had done a few things right. When I’m sailing solo I always give myself lots of room and lots of time to get stuff done, and even though I had crew last night, I’d done the same.

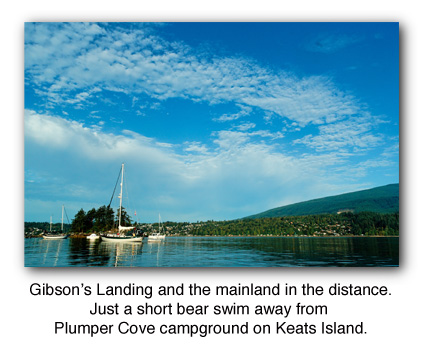

We were 2 or 3 cables off the shore, so had a bit of sea room – lots of time to get the sails back up if necessary. We also were not on a lee shore. Horseshoe Bay is a busy ferry terminal and I always raise and douse sails well away from the ferry track. I was glad I had done so tonight, as I looked out into the dark to see the Bowen Ferry approaching.

I popped the lid on the outboard and realized I couldn’t really see too much in the dark, and wasn’t too thrilled with the idea of trying to fiddle with the recoil line in a sloppy chop. The Evinrude has a great big flywheel up top, and sure enough, it’s got a groove built-in for wrapping a line.

The groove is quite narrow – probably the same as the recoil line itself which I learn later is 5/32″ line – and I don’t have anything that small on the boat. I did manage to find a couple of feet of 1/4″ line in my skipper bag, and though it was barely recessed in the groove slot, I was able to wrap it ONCE around the flywheel.

One pull.

Two pulls.

With only one wrap around the flywheel, I’m not getting much momentum, but the motor is a notoriously good starter, so I figure it’s going to fire.

Should I choke and risk flooding it?

Sure, let’s choke.

Choke.

One more pull. Choke Off.

Pull. She fired right up, and we motored in without further mishap.

It was a good lesson though. I’m always pretty cautious when dousing sails and motoring up to get to the moorage. I’ve been caught on a lee shore before, and it isn’t anything I ever want to repeat, so I tend to give myself a lot of room – I was glad I did on this night.

No matter how well maintained your vessel – things break. I keep Madsu is top shape, and since the outboard had been serviced in the spring, including a new recoil line, this caught me totally unawares.

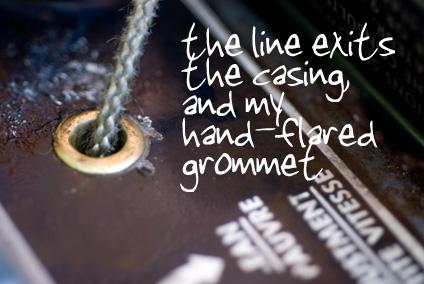

What I didn’t realize is that the recoil line was chafing against the casing – there is a soft metal sleeve or grommet to keep chafe down, but it had worn through and the line was slowly cut through from friction against the casing. I now have an emergency line of the right width in my bag, in case I have to use the flywheel to start up again.

Finally, I was grateful for a motor that starts well, and another good reason to keep it serviced and running properly.

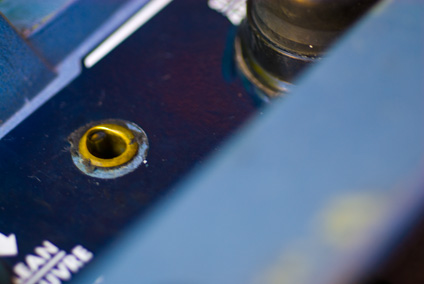

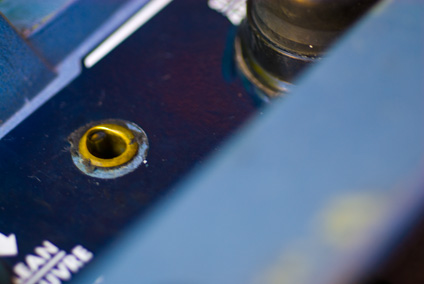

This is the grommet meant to protect the recoil line as it passes through the motor casing. It’s soft metal, brass I think.

You can see how it’s worn away in one spot – that’s because of the extreme angle required to pull the line when the motor is down and in the water. The starter handle sits tight against this grommet when the line is attached and I hadn’t noticed how it had worn right through. Every pull was cutting through the line.

The Repair:

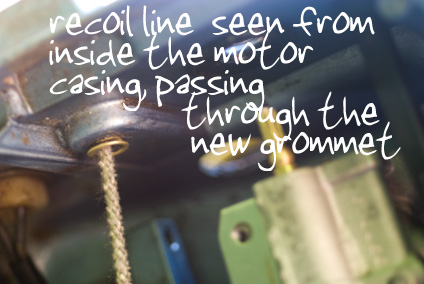

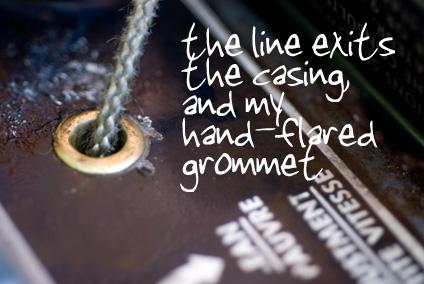

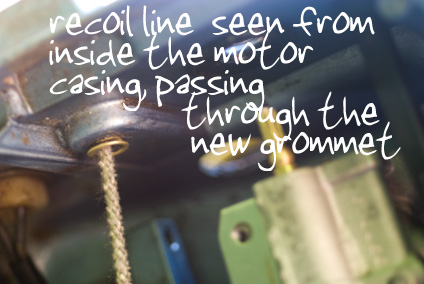

I did get a new grommet from Lorship Marine on Victoria Drive. It’s essentially a tube, pre-flared at one end. You insert it from the inside of the motor casing, then hand flare the outside.

Once I’d cut out the old grommet, I had to remove part of the carb in order to be able to insert the grommet through the casing.

Then I had to flare the tube on the outside – I found a flaring tool at Home Depot which got things started ok, then finished off withe some gentle work with the ball peen hammer. I had to jam a piece of hardwood in to support the inside end of the grommet while I flared the outside. The flaring tool did an excellent job of getting a nice consistent shape to the start of the flare, and with some light touches with the hammer, I was able to get a really nicely shaped grommet by the end of it.

I had taken the motor off the boat and worked on it at home. It would have been a really difficult job with the motor still on the boat, so I was glad I was able to do the repair here, as opposed to while out cruising.